Services

Medical Devices and Prosthesis

Leveraging our team's substantial background in the medical sector and the specialized expertise of our engineers in 5th axis machine centers and multi-axis lathes, FBJ is proficient in managing a wide variety of machining processes. These capabilities are customized to cater to the entire spectrum of part shapes and materials typically encountered in medical device manufacturing. This includes prosthetics, surgical instruments, as well as the equipment and tools routinely employed by healthcare professionals.

Aerospace Industries.

Drawing upon our vast expertise in machining a diverse array of alloys and intricate configurations, we have the capability to craft tailored manufacturing strategies for every component we produce. This proficiency enables us to consistently deliver high-quality products that not only meet but consistently exceed our customers' expectations in terms of value and on-time delivery.

Defence

We specialize in the production of extremely precise components with exceptionally tight tolerances. Currently, FBJ serves as CNC machine shop for organizations in the Military and Defense Industry. Our commitment to staying at the forefront of technology allows us to remain up-to-date with the latest advancements in military components. We possess the capabilities to achieve the utmost levels of precision and accuracy.

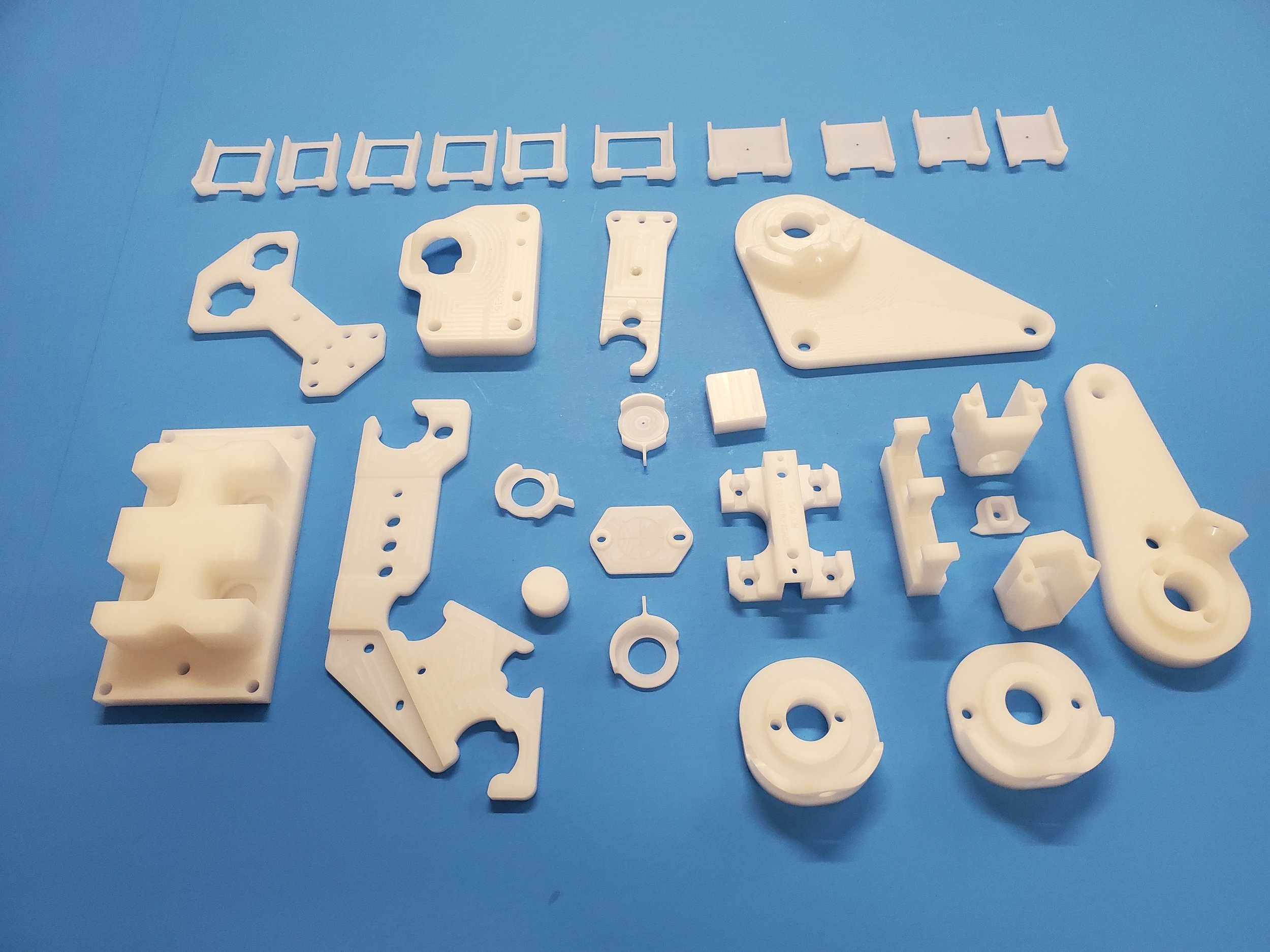

Tooling & Prototype

Our standardized equipment setup creates a user-friendly and efficient environment, making it ideal for rapid tooling, specifically for fixture fabrication.

Prototyping: The FBJ Engineering team leverages cutting-edge technology to establish the most exacting prototyping method in the realm of rapid manufacturing.

End-Use Production: The impressive surface quality, extensive material versatility, and meticulous tolerance control have solidified CNC machining as the preferred technology for manufacturing end-use parts.